Multi-Compartment Treater Vessels

Cascade was tasked with cleaning a treater vessel that posed complex internal challenges. The vessel contained multiple internal walls, compartments, and dividing plates that obstructed access and complicated traditional cleaning methods. Entry was restricted to just three 36” manways and three 12” reducer plates, requiring precise tool maneuvering and increasing safety concerns. Historically, cleaning similar vessels manually would take 7 to 8 days, with significant confined space exposure for personnel.

SOLUTION

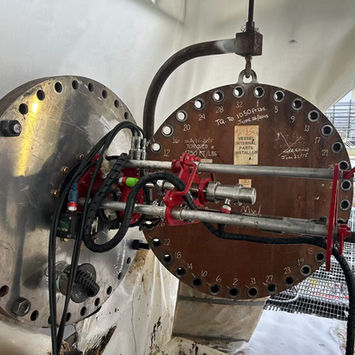

Cascade utilized specialized Vessel Cleaning Tools (VCTs) to carry out a fully robotic, no-entry cleaning operation. These tools were designed to navigate the vessel’s intricate internal layout, including narrow compartments and tight spaces. Robotic systems were carefully inserted through existing manways and reducers, delivering high-pressure cleaning to all interior surfaces without the need for extended human entry. This approach eliminated manual scrubbing inside the vessel and drastically reduced confined space risk.

RESULTS

Using the VCT system, Cascade completed the cleaning of each vessel in just two shifts, reducing total cleaning time by over 90% compared to manual methods. The operation saved 864 confined man-hours, significantly reducing the number of workers required to enter hazardous environments. The cleaning was thorough, efficient, and met all operational standards—allowing the customer to return to production quickly.

IMPACT

Faster turnaround, safer execution, and 864 man-hours removed from confined space risk.